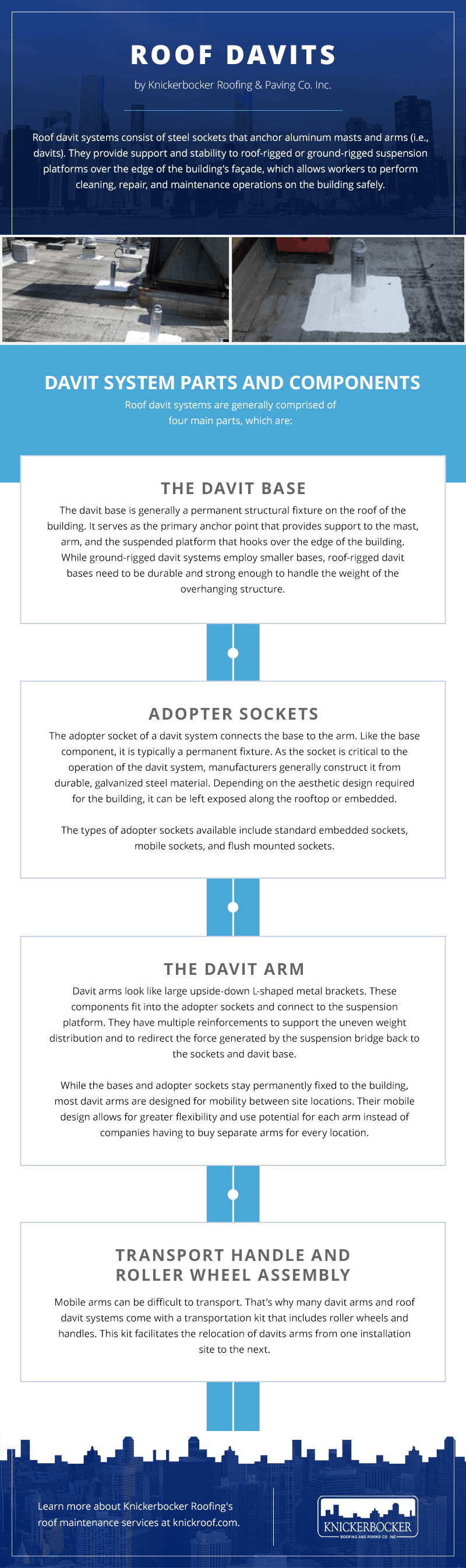

Roof davit systems consist of steel sockets that anchor aluminum masts and arms (i.e., davits). They provide support and stability to roof-rigged or ground-rigged suspension platforms over the edge of the building’s façade, which allows workers to perform cleaning, repair, and maintenance operations on the building safely.

Davit System Parts and Components

Roof davit systems are generally comprised of four main parts, which are:

The Davit Base

The davit base is generally a permanent structural fixture on the roof of the building. It serves as the primary anchor point that provides support to the mast, arm, and the suspended platform that hooks over the edge of the building. While ground-rigged davit systems employ smaller bases, roof-rigged davit bases need to be durable and strong enough to handle the weight of the overhanging structure.

Adopter Sockets

The adopter socket of a davit system connects the base to the arm. Like the base component, it is typically a permanent fixture. As the socket is critical to the operation of the davit system, manufacturers generally construct it from durable, galvanized steel material. Depending on the aesthetic design required for the building, it can be left exposed along the rooftop or embedded.

The types of adopter sockets available include standard embedded sockets, mobile sockets, and flush mounted sockets.

The Davit Arm

Davit arms look like large upside-down L-shaped metal brackets. These components fit into the adopter sockets and connect to the suspension platform. They have multiple reinforcements to support the uneven weight distribution and to redirect the force generated by the suspension bridge back to the sockets and davit base.

While the bases and adopter sockets stay permanently fixed to the building, most davit arms are designed for mobility between site locations. Their mobile design allows for greater flexibility and use potential for each arm instead of companies having to buy separate arms for every location.

Transport Handle and Roller Wheel Assembly

Mobile arms can be difficult to transport. That’s why many davit arms and roof davit systems come with a transportation kit that includes roller wheels and handles. This kit facilitates the relocation of davits arms from one installation site to the next.

Categories and Types of Roof Davits

The type of davit system employed varies based on the requirements and restrictions of the job. Some of the most common types of roof davit systems employed include:

Material Lifting Davits

Much like a crane, this type of davit system is used to lift cargo and non-personnel materials. Facilities use these systems when they need to transport bulky goods to the rooftop of a building or carry materials from an elevated location to the ground.

Personal Lifting Davits

Roof davit systems that carry people are often referred to as “personal lifting davits”. They can carry people up and down the side of the building for maintenance and repair operations along the sides of buildings. These operations can include tasks such as replacing windows or maintaining the exterior facade.

Motor-Powered Davits

Motor-powered davit systems provide greater power and control than hand-powered davit systems. They are suitable for lifting and lowering heavy and bulky loads, such as HVAC systems, tools, and maintenance equipment, and are commonly used during construction or repair operations.

Hand-Powered Davits

Hand-powered roof davits are less powerful than motor-powered systems. However, they are much easier to assemble and disassemble, making them suitable for time-sensitive, light-load lifting and lowering applications.

Ground-Rigged Davits

Ground-rigged systems lift suspension platforms off of the ground rather than lower them from the roof. These systems generally have smaller arms and require less space than roof-rigged systems.

Roof-Rigged Davits

Compared to ground-rigged systems, roof-rigged davits use taller and larger arms that have greater roof space requirements. These systems can employ larger, permanent powered platforms and are suitable for buildings with unique exteriors.

OSHA Requirements for Roof Davit Systems

In above-ground operations, safety is paramount. Workers who step onto suspension platforms generally use multiple safety systems and backup systems—such as lifelines tethered to separate roof anchors—to minimize the risk of injury to life and limb should the suspension platform or roof davit system fail.

To ensure that davit systems don’t fail in the first place, the Occupational Safety and Health Administration (OSHA) outlines several requirements—including in Section 1910.27—for the safe design, construction, use, and maintenance of davit systems.

Design specifications for davits that comply with OSHA requirements include:

- ASTM A36 steel construction

- Fully galvanized finish to ASTM A123 standards

For building owners and managers, OSHA requirements include:

- Inspecting, testing, and certifying every davit system in the field after it is assembled

- Informing employees that the davit system meets OSHA standards

Section 1910.27 requires that building owners and managers of new and existing buildings receive OSHA certification before putting a davit system into use. Additionally, even if the building does not regularly use its davit system, it must undergo recertification at a minimum of every ten years. For davit systems, with adhesive, epoxy, or chemically bonded anchorages, the building must perform testing and receive recertification every five years. For all davit systems, written verification of the system’s certification must be given to any contractors for use in job hazard analysis (JHA) or site-specific safe work plans.

Knickerbocker’s Roof Davit System Capabilities

At Knickerbocker Roofing, we provide a full range of high-quality roof davit system services. Our capabilities include:

- On-site davit installation. Our expert team installs our davits. . This ensures greater quality control and compliance with safety, industry, and OSHA regulations.

- Davit manufacturing and assembly. We provide a comprehensive array of services, so you only need to place one call for your roof davit system needs. Our team will assemble and install roof davit systems according to the highest safety standards for superior performance and reliability.

- Installation of contamination protection. Some buildings, such as hospitals, need roof installation and repair operations to take place with additional preventative measures. At Knickerbocker, we have the capability and experience to provide contamination protection for worry-free roof installations and repairs.

- 24/7 emergency services. Our team can provide emergency roof and leak repair so your building stays safe and operations can continue inside. Our coverage area includes Illinois, northwest Indiana, and southeast Wisconsin.

Contact Knickerbocker Roofing for Your Roof Davit System Needs

Knickerbocker Roofing & Paving Co., Inc. is the leading provider of roofing services in the Chicago area. Our expert team consists of roofing repair professionals, tradesmen, and industry experts, which allows us to provide the highest quality industrial and commercial roofing services.

Roof davit systems need to be high-quality, properly treated, and easy to operate. At Knickerbocker Roofing, we have the skills and knowledge to fabricate, assemble, and install roof davit systems that you can trust.

In addition to our roof davit system services, we also offer a wide range of other roofing services, including:

- 24/7 emergency roof repair services

- Green roofing services

- Low and steep slope roofing services

- Roof maintenance services

- Architectural sheet metal fabrication services

To learn more about our roofing services, including roof davit fabrication, assembly, and maintenance, or to partner with us on your next project, contact us or request a quote today.